LegoLoom Part 2: Existing Work

After thinking for a bit about a mechanical device that computes a fake punched card for the 1800s Jaquard loom, I figured it appropriate to first look at mechanical logic done with Legos. Fortunately, some enterprising people have already created such devices.

Lego Logic

2in1 Bricking has some rotational logic gates. Although gears work much better than a push/pull over long chains of logic, I see that some of these designs have too much friction and the K-map that I performed for Rule 30 previously showed a shallow depth of computation.

Moving on to BD Technic, we have some push/pull. These circuits attract me immensely due to the very small piece count per gate. Since I expect to have >100 warp threads on the Jacquard, it would be wise to keep the costs down.

Conway’s Game of Life

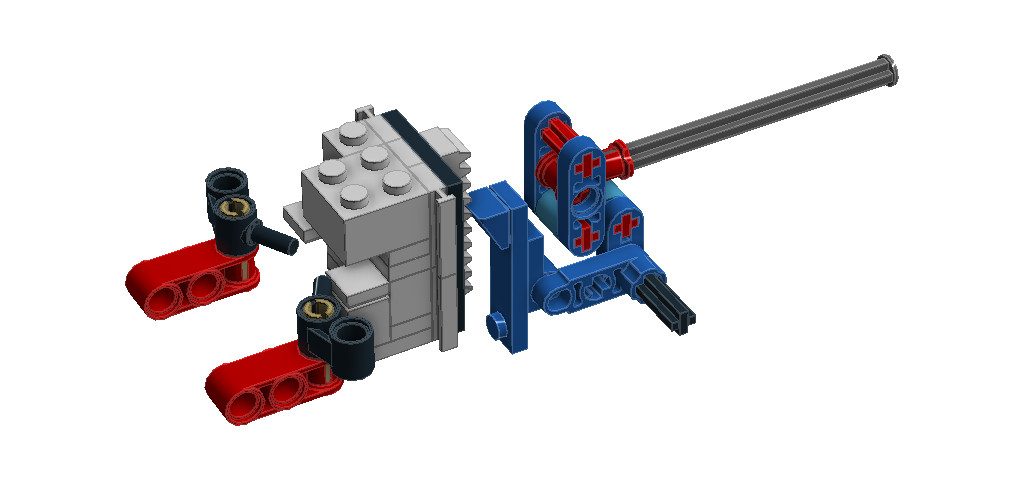

Further research revealed an example of Conway’s Game of Life. Some fascinating details on the Eurobricks forum. This mechanism has some really impressively clever design. At the heart it has a removable computation brick, read by a couple of levers for the on=orange off=black cell display, which ratchets up against gravity with each on neighbor, polled by a rotational toggle. The polling is incredibly clever. Beautiful piece of engineering!

AncientJames uploaded the designs to Bricksafe, so I was able to order the parts and build one of the cells myself. Which helped me get a hands-on feel for how the mechanism works. I though building one would take about an hour, perhaps two. It reality it took six, because Stud.io doesn’t do a good job of auto-generating instructions. The order in which you build up the parts really matters in assembly and some portions too a handful of attempts before I figured out the correct order.

I don’t think that I can use a mechanism like this, because of the parts cost. The single cell amount to $40. And the linkages seems like they lack the robustness I need for faking out a Jacquard punchcard.

Lego Looms

All the existing work seems to use yarn. While that’s certainly fit for Lego stud sizes, it doesn’t make a very tight weave. We’ll get to why that’s important in the New Goal section.

Nico71’s Small Mechanical Loom

Nico71’s site hosts plenty of informative nuggets about this small mechanical loom. It looks like it was an effort in 2011-2012 at some Lego shows and then sat dormant for a few years before getting an upgrade in 2015. This loom only weaves a few threads of yarn on the plain weave pattern.

Turns out that creating a loom in Lego faces a handful of challenges:

- Tension on the warp threads, moving the cloth roll and warp beam the correct amounts with each weft pick

- Ensuring that the shuttle completely moves across the shed, and doesn’t stick on any warp threads or stop in the middle because of friction unwinding the weft spool

- Synchronizing the many steps of loom operation

Weav3r

Jander highlights a much more sophisticated Jacquard loom with details spread across a handful of articles on his blog. After some upgrades this loom includes quite an impressive array of components:

- A tensioned spool for each warp thread

- A winder for all those spools

- Individual heddles for each thread

- A pattern scanner, so you can express the weave as a Lego picture

From a design standpoint this project is a goldmine! I’ve noticed that each weft pick takes quite a bit of time to set the pins in the Jacquard mechanism.

A New Goal

Recall that I started looking into the Lego looms as a distraction from looking at logic with the original goal of faking out a large-ish punchcard. But I’m concerned about Rule 30 having long runs, which would make the fabric weak. Which makes me want to prototype some weaving at home.

So I figured I’d build a Lego loom. But all 2 of the examples — yes there really are very few, this must be a niche area — I see online use yarn.

If I’m going to build a loom for prototyping the long runs, I might as well make it programmable, which means I can return to The Hat or Spectre aperiodic monotiling. And if I’m going to do that, I might as well make it a high-threadcount weave. And if I’m going to do that, I might as well get a glass of milk print out the build instructions for the loom!

Which means I’ve adopted a couple of profound new problems

- An instruction book rendered at 1024 x 768, means I have a large number of threads. I can fit on the short side, but would like it to be paper sized. Thats 8.3 inches or about 100 threads per inch.

- Lego studs are 8mm apart, so 100 threads per inch translates to 2.54 threads per stud. Not much space.

- With about 800 threads on the warp, I’ll need a fast mechanism to update the heddles for each weft pick and a special design for the beater.